|

When Western Electric presented their new moving coil dynamic microphone, the 633A, in 1937, they did not beat about the bush, the main goal was production at low cost, but without sacrificing quality or ruggedness.

By 1937, microphones were no longer just meant for broadcast, movies and recording, thus the 633A was intended for a wide variety of uses, like PA and quality paging systems in schools, hospitals, restaurants and hotels. Only when extremely high fidelity sound was deemed necessary, the 630 'Eight-ball' was advised.

The new 633A did become widely used in broadcast though: for remote pick up, sports commentators, simple tasks or simply as spare microphone. The shape of the 633 lead to its nickname: the 'Salt-shaker'. The number of necessary parts to produce a microphone was radically reduced, but it needed very precise production.

The thin aluminium diaphragm and the voice coil of the 633A were glued together, they were extremely fragile, and were handled with care by suction instead of human hands, to avoid damage during assemblee. The diaphragm and voice coil joined together with the magnets formed the complete capsule which was just 35mm in diameter and 18mm deep. A fine gauze protected the innards against metal particles and dust. The three fins amplified high frequencies and protected the capsule if a human hand covered it.

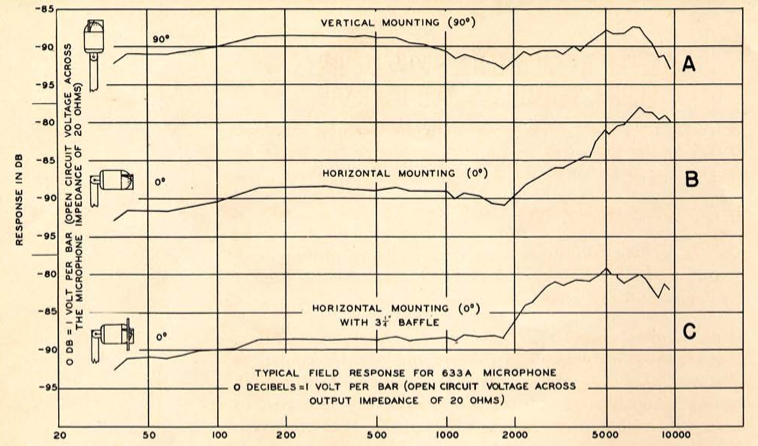

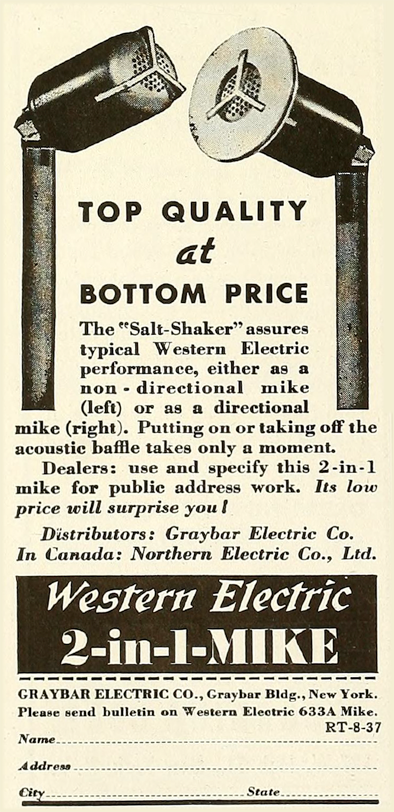

The Salt-shaker was omni directional, registering 40-10.000 Hz, or semi directional between 1000-3000 Hz, with an optional baffle, 83 mm in diameter, attached to it. It was small, compact and light in weight. WE advertised it as 'the two in one mike'.

The 633A could be screwed into a floor or table stand, or into a swivel joint. The thread of the mic was non standard, making WE stands necessary. It could also be hung suspended from its cable. An adapter made it possible to use it with the same connector as used by the 630. The original casing consisted of two parts, later three, which simplified assemblee.

The microphone had been developed at Bell Labs, in New York, and was produced at the giant Hawthorne factory, near Chicago, which had been built in 1905. By 1910, almost six million telephones had been made there, by WE's large work force, which in its heyday rose to 48.000. The workers were studied to optimise production.

The 633A became the first microphone to be produced in large series. Before everything had been done by hand, which was of course much more costly.

This model was also built in Canada, by Northern Electric, but not made by STC in the UK, unlike the earlier 618 and 630.

When WE was forced by US anti trust authorities to sell their audio division, in 1949, the 633A was continued by Altec until the end of the sixties. Altec also produced a version that was updated as 633C, with a mylar diaphragm, an extended frequency reach of 30-12.000 Hz and a transformer for 150 Ohm output, instead of the transformerless 30 Ohm output of the 633A.

In STAX productions, the 633A was often used for recording the snare drum sound, placed upright next to it. The sound clip proves this capsule stil functions, but without a doubt the thin sound is not showing what it must have sounded like originally. If you want to hear what it sounded like, check out the 1964 Beatles concert at the Washington Coliseum, on Youtube.

These microphones can stil be found on the second hand market, but they are not as cheap as when they were first made.

These and many more types feature in my book Witnesses of Words. More information about that can be found at www.witnessesofwords.com

|

|

|

|

|

Above: the original two-piece and a three-piece version of the WE 633A

Below: frequencie chart, sound, back of the Northern Electric version, capsule,1937 ad & Beatles George and John with a WE 633A, in 1964 |

|

|

|

|

|

|

|

Video's

Video's Contact

Contact